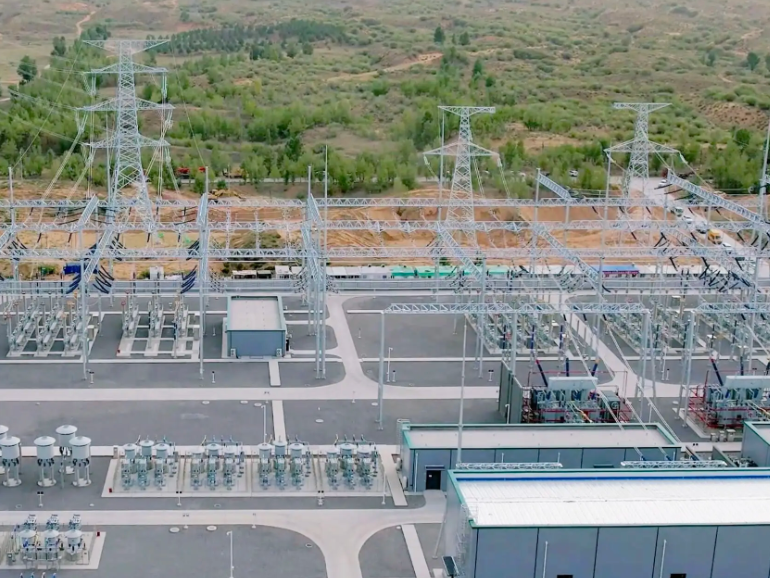

The rated voltage of electrical equipment on the user side, such as household appliances, factory motors, etc., is generally low (such as 220V, 380V, etc.). When high-voltage electricity is transmitted to the substation near the user, the step-down transformer in the power station will gradually reduce the high-voltage electricity to a suitable voltage, and then distribute the electricity to various users through distribution lines. It is evident that substations play a crucial role in the transmission of electricity.

However, the operating conditions of substation equipment are complex and variable, and are easily affected by various factors such as load changes, environmental factors (such as temperature, humidity, dust, etc.), and power grid faults.

The cause is that the power station contains a large number of electrical equipment, such as transformers, circuit breakers, isolating switches, transformers, etc. These devices will experience significant aging and performance degradation due to various stresses such as electricity, heat, and machinery during long-term operation. For example, the insulation material of the transformer winding will gradually age with the increase of time and operating temperature, and its insulation performance may decrease, which may cause short-circuit faults. Through online monitoring, real-time operation parameters of equipment can be obtained, such as temperature, humidity, partial discharge, etc., to detect signs of equipment aging in a timely manner and prevent faults in advance

To solve the problems of "under control", "controllable" and "easy control" in the safe operation of substations, our company has launched the intelligent comprehensive auxiliary monitoring system solution DX-BTS100-ZF for substations, which is committed to comprehensively ensuring the safe and stable operation of substations and achieving intelligent management.

The substation intelligent comprehensive auxiliary monitoring system is a comprehensive management system that integrates multiple high-tech technologies. It can monitor the operating environment of the substation in real time (such as temperature and humidity, water immersion, smoke, wind speed, arc, etc.), provide various functions such as face capture, infrared fill light, and linkage monitoring through video monitoring, and realize the linkage or remote control of intelligent control devices (such as relay modules, flow fans, water pumps, etc.). At the same time, it combines electronic fences, infrared radiation and other safety prevention devices and access control visual intercom systems to comprehensively improve the safety management level of the substation.