Let's get to know bolts. A bolt is a fastener, usually equipped with a nut, that is used to tightly connect two or more parts together. In transmission lines, bolts are mainly used to connect key parts such as pylons, insulators and conductors. Due to their simple structure and reliable connection, bolts play a pivotal role in the construction and maintenance of transmission lines.

Do the bolts come loose too?

YES. Loose bolts can be caused by a variety of factors, including material fatigue, environmental erosion, improper installation, or prolonged exposure to mechanical vibration. In the case of transmission lines, wind, temperature changes, and changes in conductor tension may have an effect on the tightening state of the bolts. Over time, these factors may lead to gradual loosening of the bolts, thereby reducing the stability and security of the connection.

What happens when a bolt comes loose?

Once the bolts are loose, the immediate effect is to diminish the structural integrity of the transmission line. This can lead to tilted towers, dislodged insulators and even broken wires, which in turn can lead to power outages. In some cases, loose bolts can also cause sparking or arcing, increasing the risk of fire. In addition, loose bolts can lead to increased maintenance costs, as the bolts need to be regularly inspected and retightened to ensure the safe operation of the line.

The solution to the problem of loose bolts can be divided into prevention and response.

In terms of prevention, choosing high-quality bolt materials, ensuring a correct installation process and using anti-loosening techniques are all effective ways to reduce the risk of bolts loosening. For example, bolts can be manufactured using materials with high fatigue resistance, or specially designed nuts can be used to prevent automatic loosening.

Regular inspection and maintenance are essential in coping with this. By using specialized inspection tools, loose bolts can be detected and solved in time.

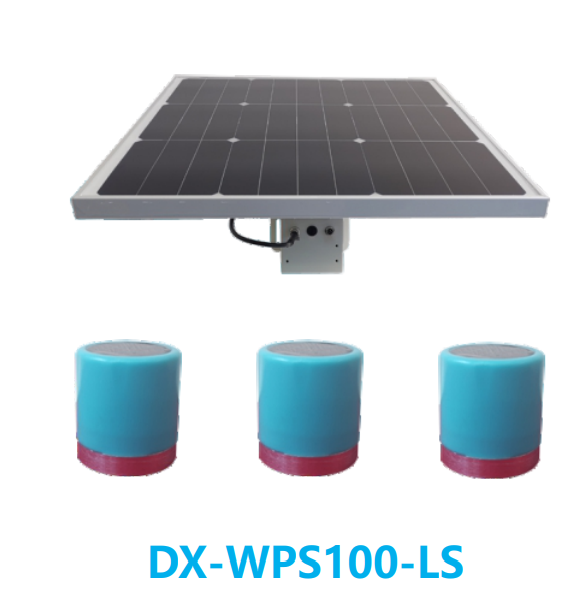

Shenzhen Dingxin Wisdom Technology DX-WPS100-LS type Transmission Line Intelligent Bolt On-line Monitoring Device, belongs to the contact type intelligent monitoring, which is an accurate and reliable way to measure bolt loosening.

That is - how can this be achieved by using the bolt itself to make a sensor? Just need to paste the strain gauges on the bolt surface (to ensure that the strain gauges can be completely adhered to the bolt surface), one or more sensors interconnected to the network, and then from a connection point to continuously monitor the remaining bolt loads, real-time automatic collection and measurement of tower bolt loosening data, and will be the data uploaded to the monitoring center, the issuance of early warning information to remind.

Monitoring of the bolted parts can substantially improve the reliability of the bolted connections and reduce the frequency of tower tilting, insulator dislodgement, and conductor breakage accidents.

In addition to the technical measures mentioned above, improving the skill level and safety awareness of the staff is also the key to preventing the loosening of bolts. Through regular training and education, staff can be made more aware of the importance of bolts and master proper inspection and maintenance techniques, thus improving overall safety management.

In this process, it can be seen that everyone's efforts are indispensable. Only by taking multiple measures and working hand in hand can we work together to maintain our power lifeline.